Full Power – Fully Operational – Unattended Operation

After almost six years since the first meeting over a few pints to discuss the concept of a Community Hydro using the power generated by Havannah Weir, Congleton Hydro has been operational for the last two weeks.

Whilst 65kW is the design target for power generated, the above snapshot was taken after running for about one hour. As the system “warms up” some of the operational losses actually decrease, especially that of the gearbox and we are quite pleased that design target is more or less achieved.

Before we could contemplate running 24hours per day i.e.unattended operation we needed to ensure that adequate site security was in place and (as mentioned in last month’s newsletter) we extend Archies blanket of safety mesh. Wayman Fabrications of Congleton have come up with an economic design to extending the mesh. Manufactured in their Congleton workshops, trial fitted on-site and then sent away for galvanising, it was installed a couple of weeks ago. A great job, by a small team, from a local company—Well Done Waymans.

Safety Mesh Extension

(Grid in the foreground is hatch (lockable) to allow ladder access to forebay tank)

Leaving the system to operate unattended may be (and definitely is!!) a significant milestone but it brings with it two potential headaches—site security and remote performance monitoring. Whilst our site perimeters are formed by the river, steep densely wooded banks and the boardwalk security access fencing (hopefully by the end of the month!!!) we can never 100% prevent access by determined intruders. To help monitor the site, not just by intruders but also for natural incursions e.g.landslip, fallen trees etc we are in the process of installing a comprehensive CCTV system. Using our 3G connection (already built into the control cabinet) we can view various site images remotely and also the history (past few weeks). This is achieved using a “mobile phone client app” called BitVision. BitVision is an easy-to-use chunk of P2P (peer to peer) network video monitoring mobile phone client software. Currently it allows us to remotely (on demand) monitor the various site cameras. When we have finished installing it, we can then “define the movement window” for each camera and the system will then auto-generate “intruder alerts” onto our mobiles –well that is the plan, we’ll see how well it works, we will not be happy to be woken up in the middle of the night by spiders crossing the camera lens!!!

Being prudent engineers, we have chosen the “hard wired” camera option as opposed to wireless. Each camera is supplied by power from a central unit and sends back a high-quality video signal to the video processing unit. One of the cameras needs to be positioned outside of its “cable spec length” and its picture quality is somewhat poor—a solution to be found.

CCTV Image of Gearbox, Disc Brake and Generator

Key to maximising the “uptime” of the system is the real time monitoring of the various system attributes not just key factors such as Power Generated, Water levels etc but the status of e.g., Gearbox and generator winding temperatures, sluice gate free or blocked with trash and so on. All in all, we have about 50 parameters that we need to monitor on a frequent basis (for maintenance purposes). Some of these have “alert attributes” e.g., gearbox overtemperature, sluice gate blocked and so on. These will generate an alarm on mobile ‘phones and whoever is “on call” will respond either remotely to clear a “gearbox oil level low alarm” or visit site for something more serious.

All this data is collected locally in the Control System computer (plc), transmitted via the 3G connection to a “Cloud “database—in our case Mindsphere. This is then made available via a suitable app onto our mobile phones /laptops.

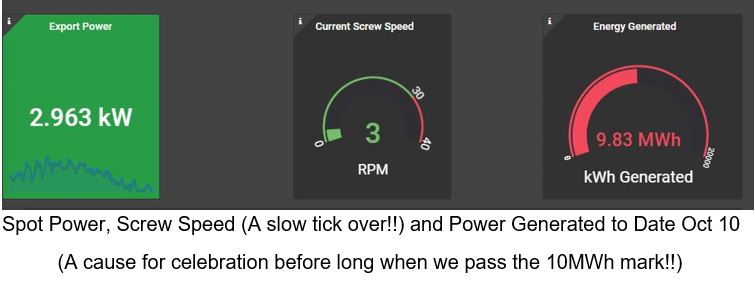

Couple of “screens” showing Power being generated, River Level, Screw Speed and Cumulative Power generated.

These screen shots were taken a couple of weeks ago, when after “the rains!! the river level was quite high. This decent amount of water in the river allowed us to reach maximum generating capacity i.e.approx. 65kW with Archie rotating 30rpm Contrast the above to a snapshot taken today (Sunday Oct 10th), water level quite low but still generating an output. As mentioned earlier, we are very pleased that we can generate at low water levels. This really does demonstrate the benefit of using a Variable Speed Drive but brings with it a worry about the increase in temperature of the inner windings of the generator, we may well fit a forced air-cooling fan onto the end of the generator to mitigate this potential issue.

Unfortunately, technical restrictions to the number of concurrent users on the app mean we cannot make access freely available. However, we are working on an interface to transfer key data— River Level, Generated power, River Level, Screw Speed etc onto our website. We will also present a “history summary” in future editions of the newsletter.

Our grateful thanks to the people who responded to our cries for Volunteers to help with the re-wilding programme. They have put in a tremendous effort over the past few weeks and great progress has been made on removing balsam, removing stones and creating a suitable tilth for seeding.

Good Progress with the Re-Wilding programme

Three Cheers for all the Volunteers

One of the Planning conditions is to remove some of the trees that are endangering the stone structure of the “Weir Island”—the structure between the weir and the sluice. Several trees need removing especially the Ash which are in an advanced stage of dieback. It was planned for tree surgeons to carry out this work a couple of weeks ago but the forecasted very heavy rain (which did not really materialise) has caused this to be postponed. The need for this work can be seen below:

An interesting photo of the Weir taken whilst carrying out the Dodgy Tree Survy. It is Curved!!

We have finally managed to get hold of the materials needed to clad the powerhouse. We have chosen “log lap” cladding, which we think will fit in nicely with the woodland surroundings.

We are doing the work ourselves, and after a faltering start are making steady progress. We will be installing scaffold to clad the wall at the screw end.

As with all such projects our future progress meetings will be dominated by arguments as to what colour wood stain shall we use—performance of Archie etc pales into insignificance compared to such topics of bike sheds and colour schemes!!!

As with previous newsletters, we hope this edition has been informative and of interest. We would welcome your feedback and your suggestions.

It may well be that now we are rapidly moving to the operational phase of the project that future newsletters will be maybe on a quarterly basis, but we’ll see how we go with information that might be of interest, e.g., Boardwalk Education Programme Interpretation Boards will be ordered and installed in the next month or so?

We are not out of the woods yet, so all please still take care and stay safe.

With best wishes from The Congleton Hydro Team

Recent Comments