The recent storms of Eunice and Franklin brought devastation to lots of areas and communities but for Congleton Hydro they brought good tidings i.e. Kilowatts from Rain!!!

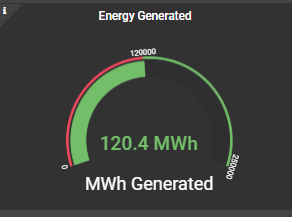

Cumulative Energy generated as of February 28th. Generation in the month of Feb was 33.2MWh—a new record despite Feb only having 28days! (Corresponding amounts for previous months Nov. 20.4MWh, Dec 31.7MWh, Jan 17.5MWh

We did however have a lot of debris that streamed into the water intake.

Many thanks to the team of Volunteers that cleared this lot out—the big stuff took some shifting. Whilst this debris did not stop us generating, it did illustrate that operating and maintaining the system generates rucks of tasks for us to get on top of and also look for design upgrades to improve the efficiency of generation. Brings me back to a Triumph Spitfire restoration. Spent several years taking the old car apart and then doing a nut and bolt restoration, quite proud that it was restored to the state that it left the factory, apart from replacing all the unplated mild steel washers with plated ones. (If only Triumph, BL etc had spent a couple more pennies on plating key components to resist corrosion they would have built much better cars). Anyway, quite pleased with the result—even a Rolling Road Dynamometer test showed it was meeting (in fact just exceeding) the specified BHP and Torque. Great, now clean hands and enjoy listening to the throaty roar as it powers through the hills—but No!! along comes the introduction of Petrol Grade E10 (10% ethanol content) which ravishes and digests the original rubber fuel pipe and seals—so back to dirty hands to replace the fuel system. But the car still looks great!!

For any readers that might own an old classic or just an old car, you can check if you are “Ethanol Resistant” by visiting https://www.gov.uk/check-vehicle-e10-petrol

Anyway, that’s enough of car restoration fantasies. Back to the hydro and out with the slide rules and log tables to grapple with A-Level Physics.

A-Level Physics in the Hydroelectric Generator

We have found by experience that we need to understand many basic principles of A-Level physics just to be able to analyse how and why the system is behaving in strange ways.

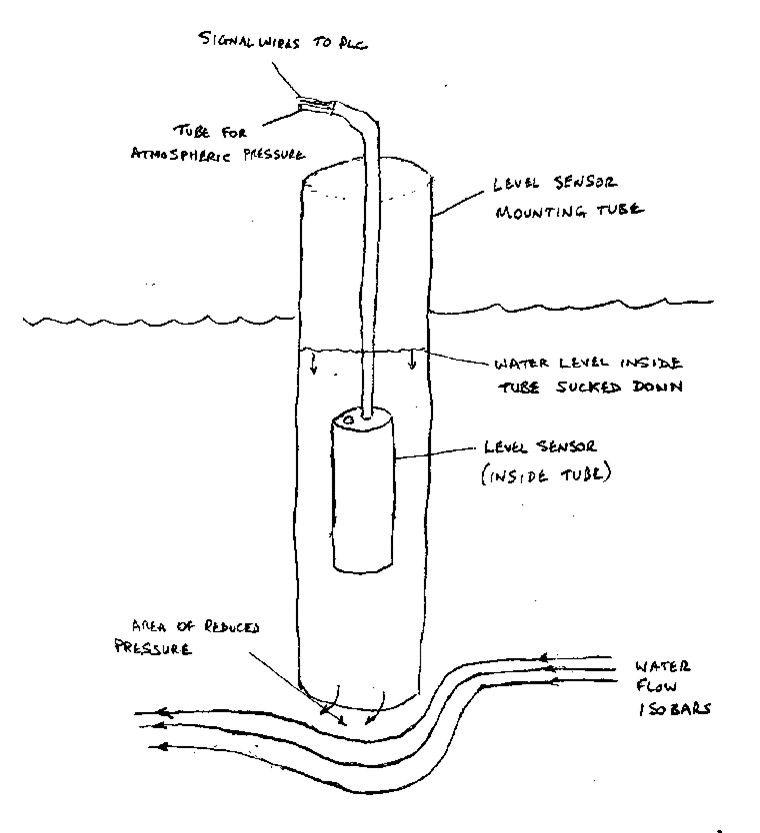

The latest manifestation of unexpected behaviour occurred last week after storm Eunice. We noticed that the weir level sensor was reading a lower water level than the gauge board was indicating by a considerable margin. The sensor was indicating a level of 6cm when the actual level was about 30cm. This was causing the control system to slow down the rate of screw rotation with a corresponding reduction in power generation when it should have been running flat out.

Curiously, the reading of weir level was correct when the gate was closed and there was no flow.

The weir level sensor is mounted in a high-tech plastic tube (usually referred to as a drainpipe!) roughly 0.5m below the normal water level. It measures the difference in pressure to atmospheric pressure to work out the water level. After some serious head-scratching, we concluded that water rushing past the bottom of the tube was artificially reducing the pressure in the pipe and “sucking” the water level down. This is due to the Bernoulli effect, first discovered by Swiss mathematician Daniel Bernoulli in 1738 and forms the basis for the lift on aeroplane wings. Bernoulli’s principle states that an increase in the speed of a fluid occurs simultaneously with a decrease in static pressure or a decrease in the fluid’s potential energy.

For those of you who would like to explore further, please read on via

https://en.m.wikipedia.org/wiki/Bernoulli%27s_principle

The next puzzle was to work out why this was first observed after Storm Eunice. The conclusion was that the top half of the trash rack was blocked by storm debris, which meant that the water at the bottom of the inlet chamber was flowing much faster than normal, hence producing more “suction” on the bottom of the pipe.

Sure enough, when the trash rack had been cleared out the sensor readings returned to normal and remained correct whether flow was present or not.

To avoid this happening again in the future we replaced the high tech drainpipe with an equally high tech length of tubular steel railing pipe, but we drilled holes in the tube every 150mm (or 6” as the oldies like to say) to ensure that the pressure inside the pipe could not be reduced by the Bernoulli effect at its base.

This is the electronic solid-state sensor we use. It is essentially a device whose electric output (4-20mA) is proportional to pressure or in our case is calibrated to measure depth of water.

Since then, the measurements have been stable with and without flow, but the real proof that the problem has been solved requires another storm to come along to re-block the top half of the trash rack!

The trash rack of course is there to prevent sizeable debris flowing into the 1.5metre diameter pipe that feeds Archie. Those with good memories will recall a newsletter article that covered the installation of this “Weholite pipe”. The pipe was installed in 3metre long sections, and the joins welded together using special “flexible joining strips”. A reminder of this is shown below.

The other day, one of our eagle-eyed volunteers noticed a sizeable “foreign object” being tossed around in the turbulence of the forebay tank. This turned out to be one of the Weholite pipe jointing strips. Why this has “un welded” we have no idea—we are currently awaiting feedback from the installer as to what the corrective action will be. In the meantime, we have not observed any degradation of the systems performance.

The errant piece of Weholite jointing strip.

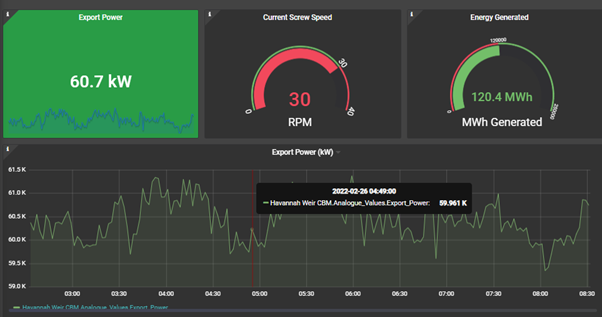

With each newsletter, we try to show the key data from the system. A snapshot of the end of the month is shown above. A question? –why the Power Ripple, it varies by almost a couple of kilowatts in an almost rhythmic manner (ignore the smaller rises and falls—just look at the bigger rhythm). This only seems to occur at higher river flow levels. Once the level drops (to 6-8cms over the weir) the rhythmic ebb and flow largely disappear, and the generation is reasonable flat. A cursory examination of key indicators i.e., screw speed, generator speed does not show any aberrations. At present we are at a loss to explain this phenomenon. Somebody has suggested it may be down to the Natural Resonance Frequency of the river itself? or perhaps even the natural resonance frequency of the Weholite inlet pipe? https://en.m.wikipedia.org/wiki/Natural_frequency

Maybe we will have to experiment with reducing the flow through to Archie to see if that makes any difference. If any reader has come across such rhythmic behaviour on any other scheme, we would welcome your feedback.

Back to the raw data. We know that some of you may be interested to know what Archie is doing right now! Well, we’re hoping to bring you some “real-time” information on the operating status of the hydro system. You will remember that Archie is monitored and controlled using a PLC (industrial Programmable Logic Controller). This, together with the appropriate software, monitors a host of variable parameters relevant to the weir and control equipment to ensure that we get the best possible performance and can safely generate the maximum possible amount of power from the water available to us. Our aim is to have some of this data available on the website so that you can view, for example, the actual water level, screw speed and amount of electrical energy currently being produced.

This, and other data, is collected and used by the PLC but is also accumulated by a data management package called Mindsphere which allows us to examine performance over time, plan maintenance and spot any issues that could affect operation. Mindsphere has an application programming interface (API) that allows safe and secure extraction of this information for subsequent processing and display.

Watch this space for more about when and how to view these details together with some further explanation about how the system works.

We also monitor the site via some CCTV cameras that we can remotely access via our mobile ‘phones. We have six cameras e.g., monitoring boardwalk for unauthorised access, “Trash Cam” to detect when trash rack needs clearing etc. Unfortunately, we have never managed to get all six cameras working at the same time, in fact despite constant care, resetting, fiddling etc we are going backwards-either cameras not working or just full of interference.

We are gradually resigning ourselves to the fact that we bought a cheap system that is probably not good enough for our demanding environment—outside cameras, electromagnetic interference (from the vsd switching frequency) and long cable runs. We are going to have to replace it with something decent.

With all the bad news—pandemic, high inflation, rocketing energy prices and now Ukraine, filling our TV screens we thought you might like some good news.

From April we will be enjoying a higher price for our generated electricity—Inflationary increase and the general rise in electricity prices.

On this note, the present (7/3) cumulative MWhr’s generated is all the more a very pleasant snapshot. (Despite, according to BBC Countryfile, the rainfall this winter being slightly below average. January was apparently one of the driest on record!)

As always, we welcome your feedback— to those of you who already provide feedback, your comments are very useful and rewarding- Thank you.

With best wishes from the Team at Congleton Hydro

Congleton Hydro Team

Dane Valley Community Energy Ltd (FCA Registration 7142)

Recent Comments