Archie Goes Electric.

Finally, Archie briefly wakes up and helps demonstrate that power can be generated from Congleton Hydro. After rucks of testing, sensor calibrating, parameter tweaking and more testing, it was time to feed his insatiable appetite and give him a much-needed drink. So, with fingers crossed, the inlet sluice gate was opened, with lots of glugging and massive bubbles (air being pushed out of pipe), the forebay tank filled, big “clunk” from the control cabinet as the incomer contactor closed, sensor outputs all giving “go command”, variable speed drive enabled, brake command to “off”, Archie started to move, and generator rotated. Hallelujah—we had Power—-it would have been quite apt for all this to have been done with Handel’s Water Music playing in the background overlayed with the Hallelujah Chorus from Handel’s Messiah!!

(For those of you wondering, Archie rotated anti-clockwise)

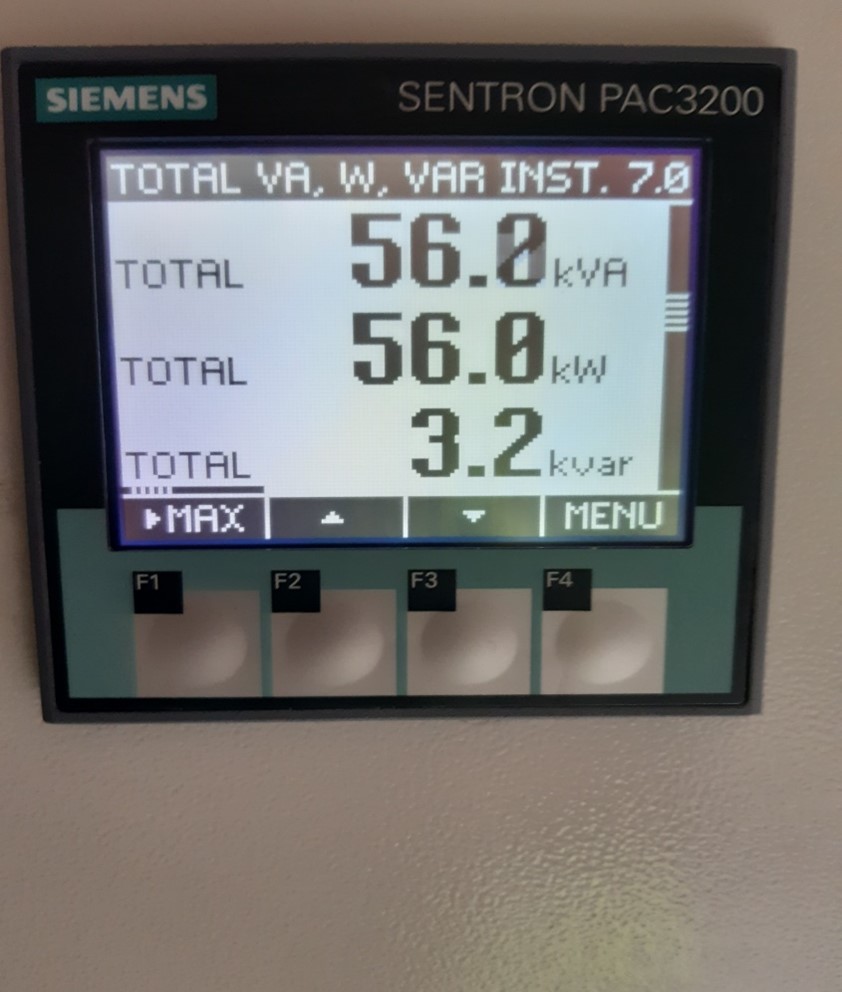

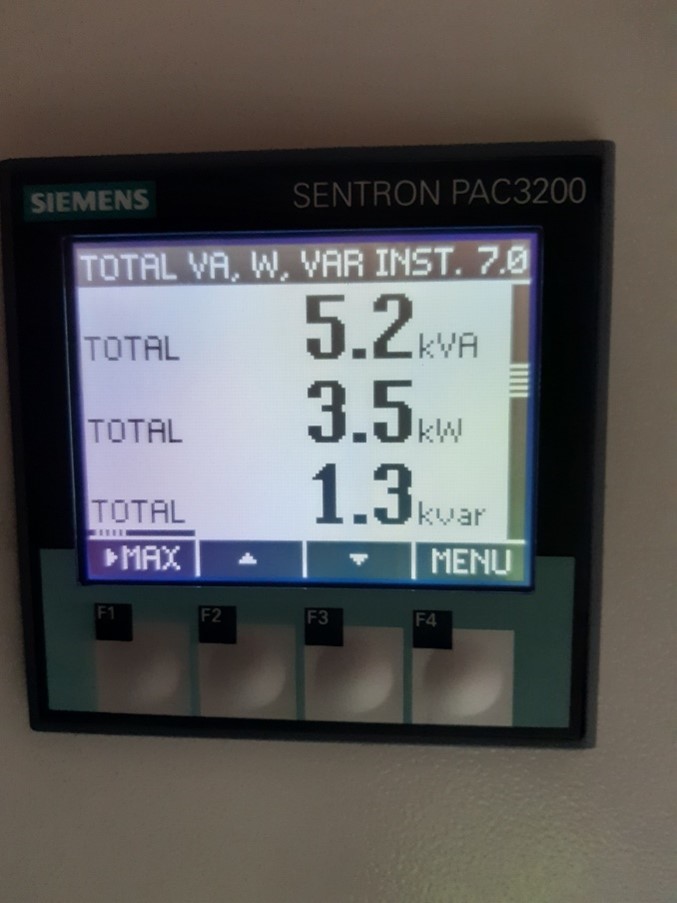

The photo above shows an output power of 56 kW at a generator speed of 1000rpm and a screw speed of 25rpm—Gearbox ratio is 1:40. This was achieved after some very short test runs at much lower powers, gradually building up as we gained confidence in the system. The photo below shows the power generated at a slow speed of just 2.5rpm

3.5 kW output with a screw speed of 2.5rpm (Generator Speed 100rpm)

Because of the very low river water levels (after one of the driest periods in recent years) we could only run for a very short period of time before water level “low” sensors kicked in. (see further below for a diagrammatic explanation of how the basic control system is “constrained” by the agreed minimum flow level).

All these initial runs were carried out in “development mode” i.e., with the system essentially running from our external programming laptop rather than the automated run sequence of the control system plc (programmable logic controller). This allowed us to manually control the sequence and timings of the various activities.

Finally, we were happy that the system was behaving in the way we designed it to operate—(or so we thought!!) and we had enough confidence to have a quick test in automatic mode—–the tension in NASA Mission Control in Houston when pressing the button to launch a rocket into space is nothing compared to firing up Archie!!!.

So, all systems go, press the start button, stand back and admire our superb automatic system take over. All good to start but then an electrifying moment—clunk, bang, sparks, lights dimming—alarm panel lit up like Christmas lights. Scared the life out of us, however, no damage done—-sparks were from the brake operating in emergency stop mode, clunk was from input breaker opening, the bang was from brake closing but why did this happen and why did the lights dim?? Checking out the system we found that the torque required to start, exceeded the setpoint current protection settings on the variable speed drive and the system quite correctly decided to shut down but not before that tremendous amount of current briefly dimmed the lights. So, back into development mode, we were able to replicate this issue and determine the cause (over-torquing requirement at startup) and modify the start-up and stopping sequences. For those interested in such detail, the start-up sequence is now to first run Archie at minimum speed (5rpm?), then open the sluice gate, then ramp up to regulated speed (automatically trying to maintain the specified weir level by adjusting the drive speed up or down). Stopping, just involves running the drive train down to a standstill, operating the brake and then closing the sluice gate.

Using this control sequence, the system was demonstrated to start up automatically, then stop when the weir level went below the Low water Level Threshold. The system then started again automatically when the weir level recovered to above the “Head Start” setting. Due to the extremely low flow rate in the river at present, we could not run for more than a few minutes, even at minimum speed, without triggering the water level low function to put the system into a waiting state.

“Home screen” of Control System HMI (Human Machine Interface) showing key indicators whilst the system is in automatic run mode.

So, not only does our revised start-up sequence work consistently, it has really demonstrated the core value of using a variable speed drive in the heart of the system, as it is going to allow us to consistently achieve saleable power over a wide range of river flow levels.

As a reminder of the basic operation of the hydro System, the Control Principle and Single Line Diagrams are shown below:

A good point to note, that during this very initial testing, the Power Transmitted (indicated on our Power Meter) was about the same power being received by Siemens at their incomer. Our original calculations that a 300mm Aluminium cable would give an acceptable loss over 1 kilometre are broadly correct.

Having proved the basic operation of the system, before we move into the commissioning stage, and then hopefully full operation, we must ensure we meet the various conditions specified by the Environment Agency in their Abstraction Licence and have received their confirmation and approval (This is now in the process of being pursued). Once this is obtained, the next stage (over a couple of weeks) is more testing and fine-tuning/optimising the control system and then hopefully OFGEM will also give their connection approval and we can start to officially generate and receive income.

At the end of June (June 25th to be precise) Dane Valley Community Energy held its AGM (Annual General Meeting) for the Shareholders of the organisation. This was carried out using a ZOOM Webinar. Whilst produced specifically for the shareholders, the overall summary of the past years’ activities may be of interest to our wider readership, and it can be read via the following link.

Basically, despite the impacts of Covid, desperate weather conditions, unforeseen ground conditions and challenging rock structures, the overall financial position of Congleton Hydro is pleasingly more or less as described in the original share offering prospectus.

The key objective of the Scheme is of course to generate annual surplus’s to be used for Community environmental/sustainability projects. Even though we will only generate revenues for part of this year, we still hope to produce a small surplus, this will be added onto next years to give the Community projects programme a good start. After the years of hard work (and much trauma and frustration!!), it is great to see our plans coming to fruition.

A small but crucially important activity completed in the last week has been the installation of the water inlet structure walkway. This will allow the detritus from the river (twigs, branches, trees even the odd sheep) to be safely “raked” off the trash screen. The walkway supports the weight of two people (plus the raked-out trash). Lifesavers – line coupled to tether posts will be worn during this activity. The walkway incorporates a lifting hatch so that the inlet gate can be accessed in the unlikely event of a malfunction (after stop logs have been fitted to stop the flow into the channel). Safety railings will now be permanently installed around the inlet structure wall.

The purchase and installation of this safety walkway has caused much grief because of the expensive quotes received from various suppliers. However, when we looked close to home (which we should have done in the first instance) we found a local Congleton company who could design and install a suitable system at a much more realistic price. They have done an excellent job.

Inlet Channel Walkway

You will recall from previous newsletters that we are working on an Educational Programme. This will be used to hopefully better inform future generations (and of course the present!!) of the importance of Energy Efficiency and the sustainability of the environment in which we live, work and play. Targeted at community groups, school pupils mainly at KS2 and KS3 levels (but also with some material for KS1 and opportunities for higher levels), significant work has been undertaken by the volunteer educational team but core progress to translate this into tangible material e.g. lesson material, information sheets etc has been severely impacted by Covid. The team have been unable to meet in real life and more importantly been unable to easily meet with schools and targeted community groups. However, going forwards we hope to rapidly capitalise on all the good work so far and have some initial materials available to better inform any site visits that might be undertaken before summer departs.

We have however made really good progress on a practical STEM Project (Science, Technology, Engineering, Mathematics) that we hope to launch later this year. This is a team construction, operation, and measurement of “How much electrical energy can you get from a bucket of water”. An outline of the concept of this project together with some photos of and results from a proof of principle lash up is attached. Hope you find it interesting.

Now that the project is coming to fruition (albeit still rucks of peripheral activities to finalise—even start!) we must ensure that all the documentation associated with the project is not only up to date but contained in a structured system that can be easily accessed for e.g., future maintenance activities. In this respect, we are desperate for a keen volunteer to help us produce a methodology that enables Congleton Hydro to have a system that ensures the safe performance, operation and maintenance of the installation, with an appropriate online and physical documentation process. A full role description can be found here:

At present site access is secured via a locked Set of Heras fencing panels. Whilst doing the job, they look temporary and a mess (well Heras is intended for temporary fencing!!) and we have only borrowed them. As well as being a pain for access, they to some extent do not reflect the excellent work what has been achieved via the main hydro and boardwalk—so they have to go asap. The question is with what?

We have two core options, a wooden fence or a stone and wrought railing insert, wall. The wooden fence will work out cheaper, but longevity will not be great. We would prefer the stone approach —using Bridestones Stone to match the stone in the bridge parapet. It is possible that we could get the stone and railings at a reasonable price via a sponsor, but the killer cost is that of laying the stones.

So, we have a desperate plea for a competent walling stone/bricklayer to please help us out. It would be a fitting entranceway to a superb community asset and also complement the existing stone of Havannah Bridge. We can provide the manual effort of mixing mortar etc (if told what to do!!), so please, please can anybody help? If so, please drop us a line at info@congletonhydro.co.uk

As mentioned in last month’s newsletter, this Autumn we need to begin the planting/seeding programme to assist the site to return to its natural state and in the process to do our best to hide/disguise some of the installed structures eg hillside retaining piles. We have done a lot of work on our plans for this and will cover these in next months issue (held over due to this month’s content).

As always, we hope you have found this newsletter to be informative and of interest. It is intended to give you a picture of how the scheme is progressing and now coming closer to fruition. We would welcome your feedback and suggestions for any topics you might like to see in future issues. Please drop us a line at info@congletonhydro.co.uk.

Congleton Hydro Team

Dane Valley Community Energy Ltd (FCA Registration 7142)

Recent Comments